Wiper assembly

Electric windshield wiper / WIPER

Product Categories:

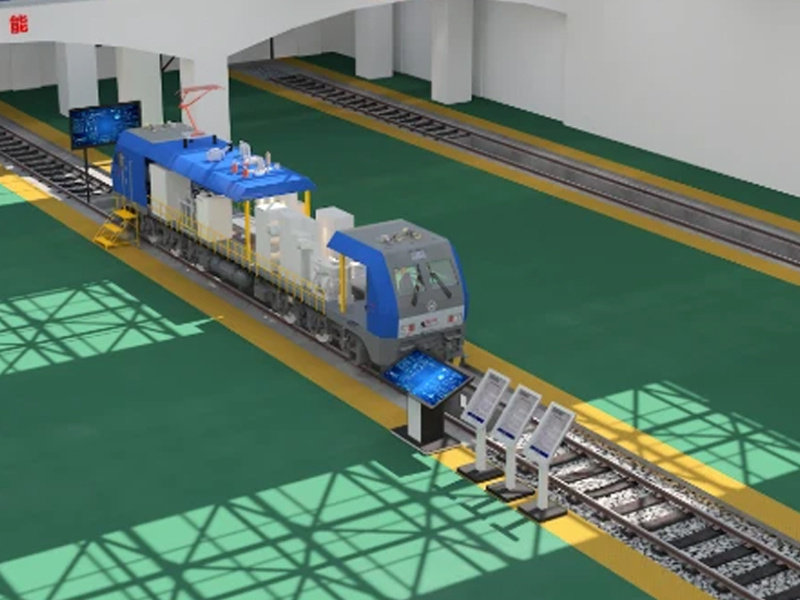

Locomotive parts

Keywords:

Changhe Electric Power

- Product Description

-

- Commodity name: Electric windshield wiper / WIPER

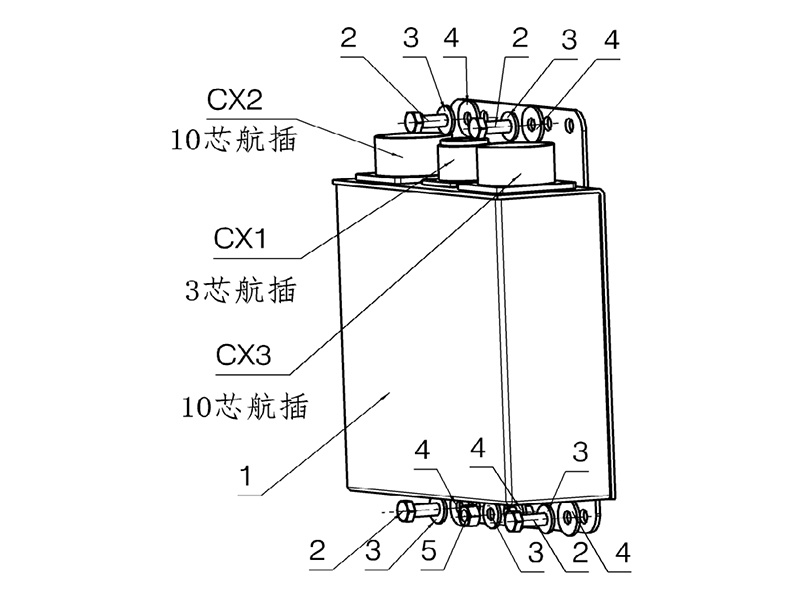

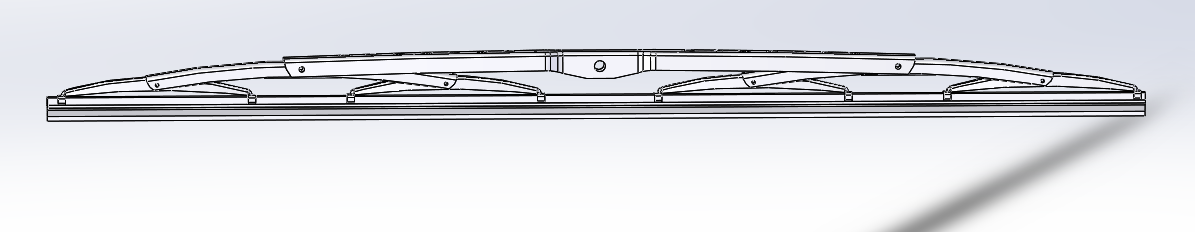

I. Scraper Assembly Section:

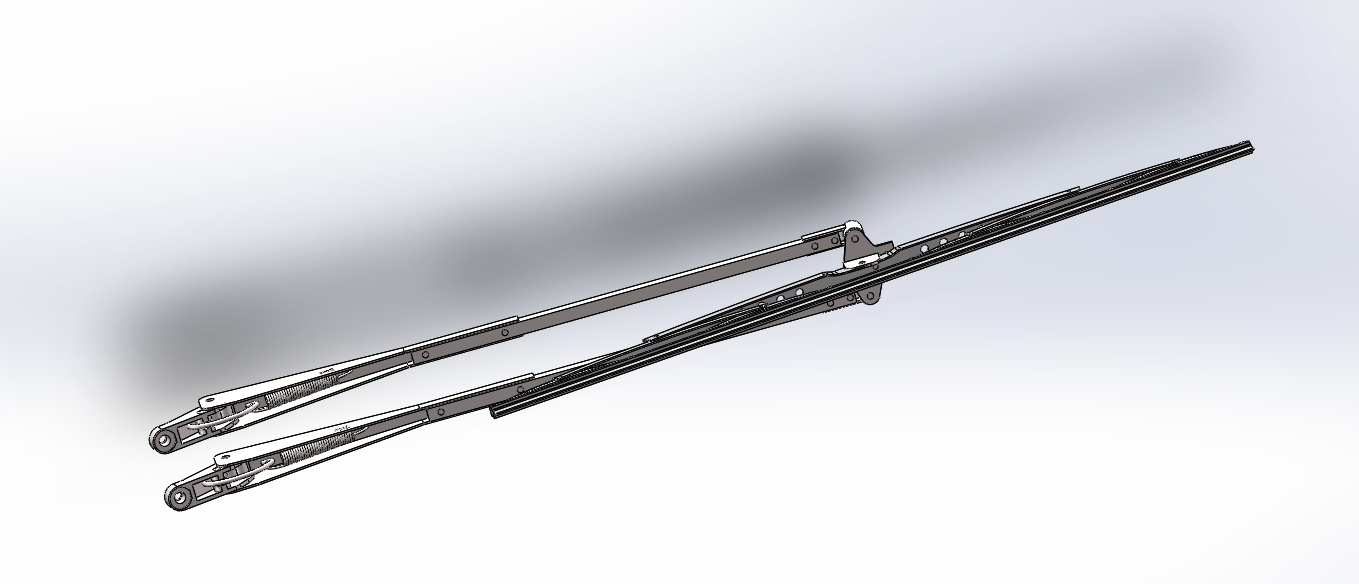

The windshield wiper assembly consists of a blade and a linkage arm. The blade is the component responsible for effectively clearing the outer surface of the glass; it can withstand the clamping force from the linkage arm and features a bracket designed specifically for installing and securing the rubber strip. The linkage arm, in turn, connects the blade to the drive motor shaft.

Scraping blade length 600–1000 mm Scrape rod length 600–1150 mm Scraping blade design life 5 × 10⁵ times Scraping rod design life 5 years Scrape rod

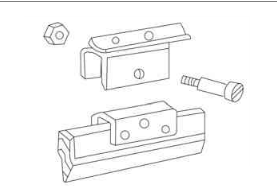

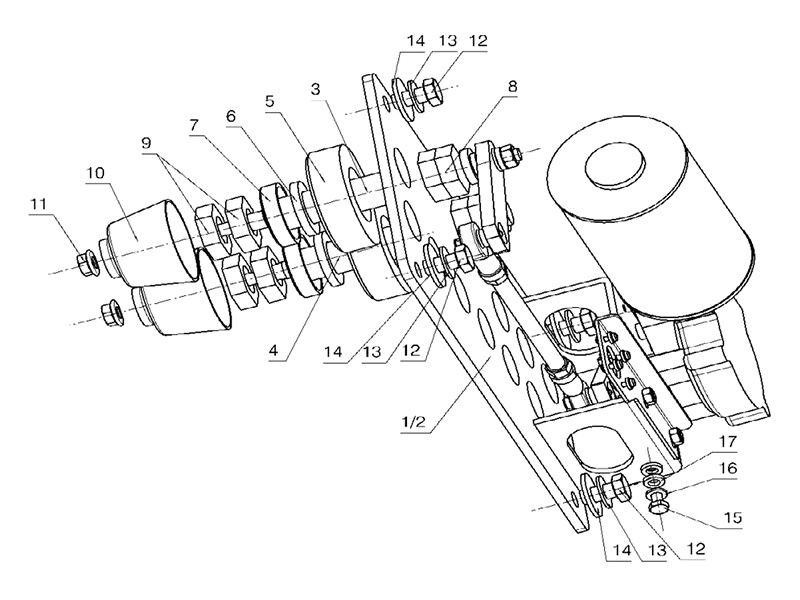

The squeegee rod features a parallelogram double-rocker mechanism, ensuring that the squeegee blade maintains a consistent angle against the floor during both left-to-right and right-to-left wiping motions. The squeegee rod is connected to the main and auxiliary shafts via helical gears, allowing for adjustable positioning. A Sure-Lock nut is used to securely fasten the assembly, guaranteeing a robust and reliable installation of the squeegee arm. Finally, the squeegee arm and blade are attached using a pin-and-socket connection.

Scraping blade

The scraper structure features a three-section bridge design with 8-point movable supports, making it suitable for scraping curved surfaces as well as large, flat windscreen glass panels.

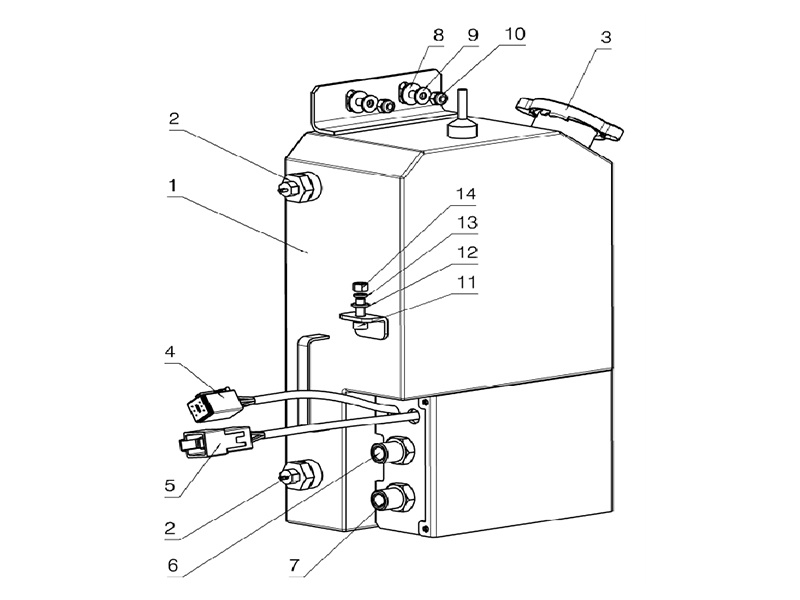

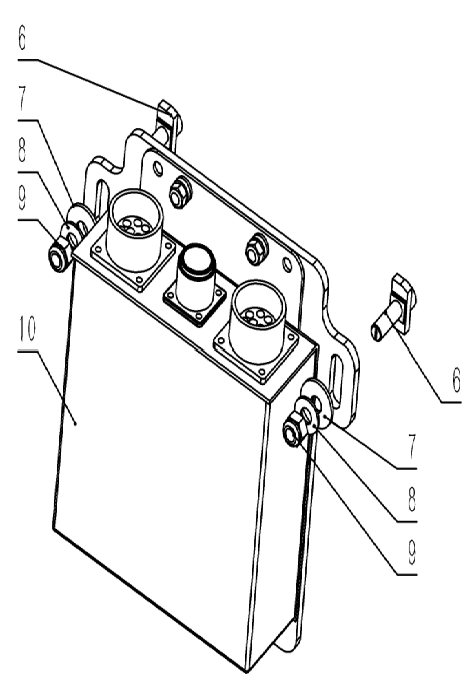

II. Water Tank Assembly Section:

The water tank assembly includes the water tank and the pump, and its function is to use the pump to deliver the cleaning fluid from inside the pump through the wiper bar nozzles, spraying it onto the front windshield for effective glass cleaning. It features an all-stainless steel tank design, with customizable dimensions tailored to the specific layout of the driver’s cab. Additionally, the tank area is equipped with a liquid-level indicator for convenient monitoring.

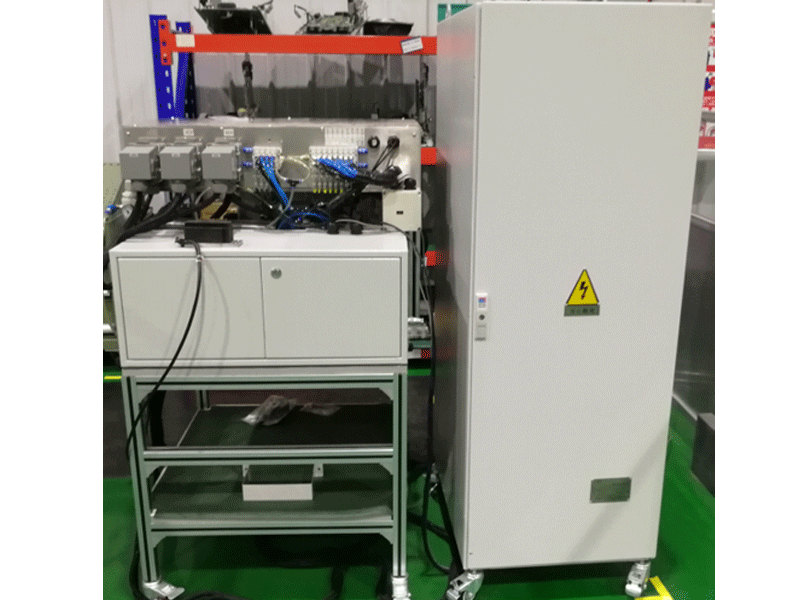

III. Drive Assembly Section:

The drive assembly consists of key components such as the drive motor, mounting plate, rotating plate, primary and secondary shafts, and a protective cover—all crafted entirely from stainless steel. It features a simple structure, stable performance, high output torque, low noise, excellent wiper action, and convenient installation and maintenance. Custom-designed professional wiper motors with an IP54 protection rating ensure reliable performance.

Standard voltage

DC 24V and DC 110V

Rated Power

80W to 180W

Operating temperature

-40°C to 70°C

Service life

2 × 10⁶ times or 3 years

4. Controller Assembly Section:

The controller features single-chip program control, ensuring precise command execution and smooth brushing motions. Its circuitry comprises a power module circuit, keypad circuit, CPU control chip, functional display circuit, control and motor drive circuit, isolation circuit, and motor driver circuit, among other components.

Standard voltage

DC110V

DC24V

Rated Power

30W

30W

Operating current

≤1A

≤7A

Maximum surge current

≤3A

≤15A

Service life

5–10 years

5–10 years

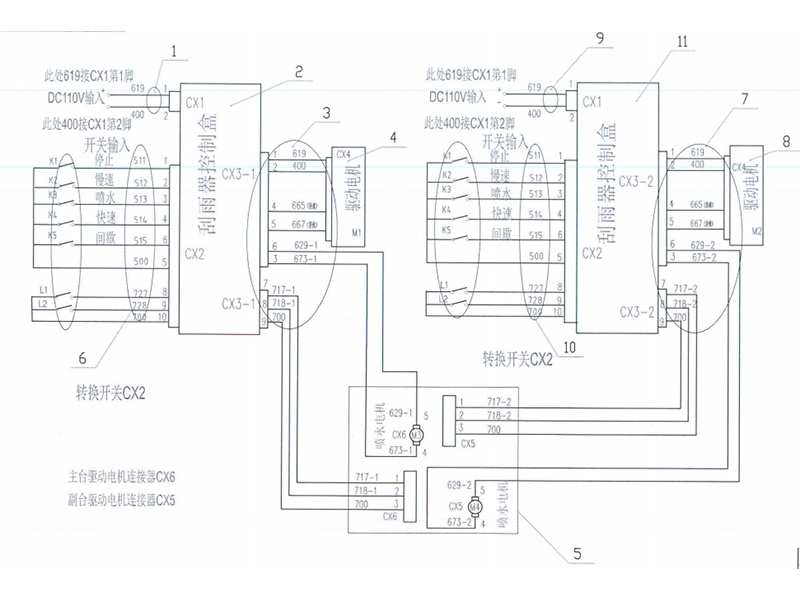

4.1. Circuit Principles

Controls the wiper arm oscillation cycle, vehicle position and washer nozzle positioning, as well as intermittent water spraying. It also features automatic protection functions for overcurrent, overload, and stall conditions, ensuring convenient and easy operation.