Introduction to the CR400AF Network Control Project

Introduction to the CR400AF Network Control Project

- Project Overview

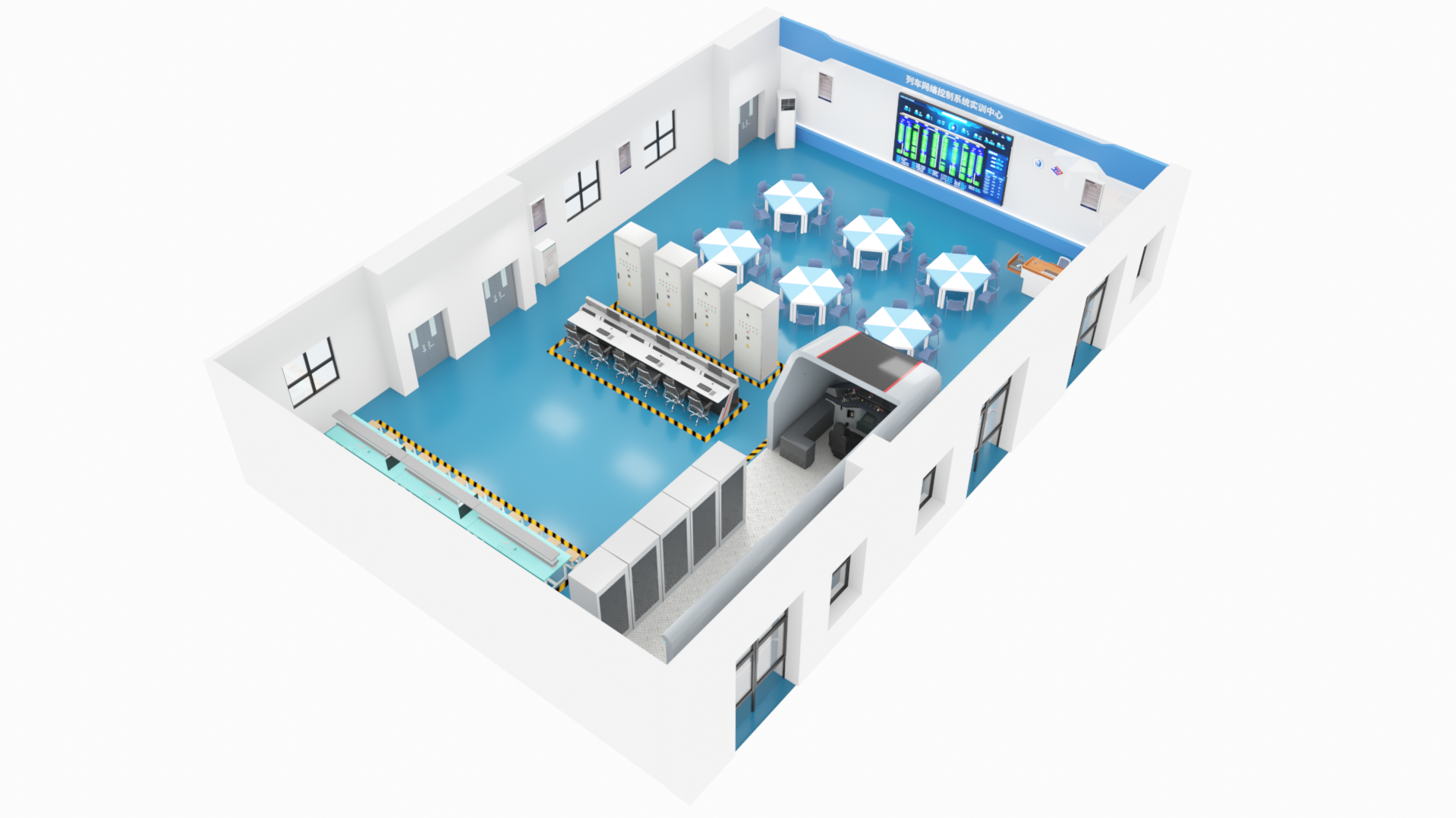

The overall design of this training lab aims to enable trainers to deliver comprehensive instruction, hands-on practice, and testing of high-speed train network control systems—simulating real-world train operations and scenarios—in a controlled, lifelike environment. By integrating the "teach, learn, practice, and research" approach, the lab helps participants gain a deep understanding of the training process, allowing instructors to tailor their guidance effectively based on each learner's unique strengths and areas for improvement.

The entire project requires the train vehicle network to support three distinct communication types: MVB, WTB, and Ethernet. Therefore, based on the actual hardware and equipment of the CR400AF high-speed train’s network control system, we’ve integrated and assembled all the related teaching facilities and equipment that mirror real-world applications. Once completed, every component in the training lab will communicate and network according to authentic train logic, enabling signal generation and transmission just as they occur in a real train. Additionally, the system can simulate real-world train-related faults, allowing trainees to practice troubleshooting and fault-resolution procedures exactly as they would in an actual scenario. Notably, at least 30 fault points must be deliberately introduced into the system, ensuring alignment with the course content outlined in "Train Network Control System Installation, Adjustment, and Maintenance." The setup includes: - One set of training lab power management system, - One onboard environment application platform for high-speed trains, - One set of network control system equipment, - Four DC distribution cabinets, - One terminal signal simulation cabinet, - Three cable-making workstations, - One cable-testing workstation, - One network testing environment system platform, - Data interaction and teaching software systems, - As well as complementary teaching equipment and thoughtful human-resource enhancements within the training facility itself.

The above outlines the CR400AF network control project, while the urban rail network control and locomotive network control training projects can also be configured accordingly.

- Introduction to the Practical Training Project

| Practical Training Project Name | Training Module Description |

| Network Topology Diagram (Basics of Communications and Networking) |

1) The main tasks and functions of the train communication network; 2) Current Status and Development of Train Control Systems at Home and Abroad; 3) The structure, features, and development trends of train communication networks; 4) Train communication interconnection and system interconnection; 5) TCN communication network standard. |

| Locomotive and Rolling Stock Network Topology Diagram (Principle Explanation) | 1) The overall structure of the TCMS for locomotives and rolling stock; 2) Locomotive and rolling stock train-level communication network; 3) Locomotive and rolling stock vehicle-level communication network; 4) Locomotive, rolling stock, and train network control system equipment and controlled devices; 5) Composition of Locomotive and Rolling Stock Diagnostic Systems and Information Transmission; 6) Functions and information transmission process of the locomotive, rolling stock, and train control system. |

| Work Specifications for the Manufacturing and Maintenance of Network Communication Cables Standard |

1) Standards and Procedures for the Manufacturing and Maintenance of Network Communication Cables; 2) Module coding cable fabrication and maintenance; 3) Power cable manufacturing and maintenance; 4) Signal input cable fabrication and maintenance. |

| Virtual Networking Assignment | Based on the topology of each vehicle network, virtual networking is performed within the software, which can automatically detect and verify the correctness of the network setup. |

| Module Installation, Inspection, and Maintenance Operations | 1) Module Installation and Tool Usage Training; 2) Daily Maintenance and Inspection Training for Modules. |

| Network Configuration Training Assignment | Based on the locomotive vehicle network topology diagram, select the modules to build the corresponding network and achieve the desired requirements. 1) Comprehensive Networking Training Exercise; 2) Practical training on checking the operational status of modules after network configuration. |

| Comprehensive Joint Training Assignment | 1) Vehicle-wide software switching and data viewing; 2) Software operation training, including setting parameters such as wheel diameter, vehicle number, and user password; 3) Complete Vehicle Logic Training; 4) Fault Simulation Training. |

| Comprehensive Practical Training on the Entire Process of Vehicle Departure and Preparation Testing | 1) Preparing for the outbound dispatch readiness test; 2) Outbound Dispatch and Preparatory Test Checklist Items; 3) Conditions for passing the outbound readiness test. |

| Emergency Training for Common Locomotive and Rolling Stock Faults | 1) Understanding common faults in locomotive and rolling stock operations; 2) Emergency measures for handling common failures during locomotive and rolling stock operations. |

| Single-module test | DIM module testing; DXM module testing; AXM module testing; |

| Module Simulation Training | 1) The physical vehicle modules DXM, DIM, and AXM in the configuration can be taken offline and fully replaced by software simulations that replicate their functions. 2) The software-simulated modules DXM, DIM, and AXM can be replaced by connecting to physical modules. |