Introduction to the Electric Locomotive Braking Project

Introduction to the Electric Locomotive Braking Project

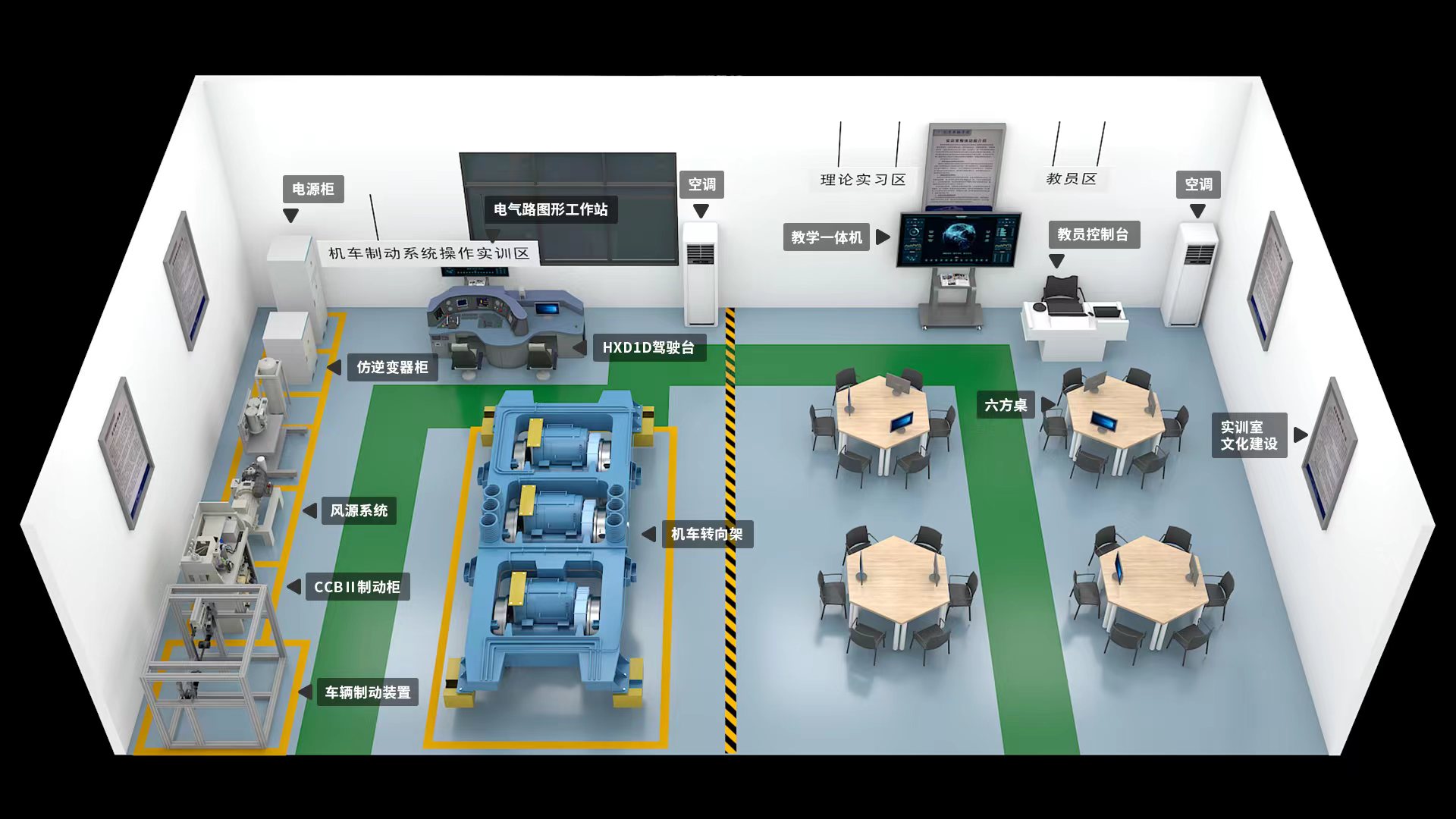

I. System Overview

The project’s main equipment configuration includes 1 driver’s cab, 1 CCBII brake cabinet, 1 bogie, 1 inverter cabinet, 1 air supply system, and 1 set of theoretical teaching area equipment, along with the construction of infrastructure for the training room (including partition walls and cultural enhancements within the training space). The entire project is built based on the HXD1C electric locomotive’s braking system as its prototype, integrating and assembling the equipment precisely according to the specifications outlined in the tender documents. Once completed, all physical interconnected components of the project will simulate real-world communication, signal generation, and data transmission processes identical to those of the authentic HXD1C CCBII braking system. Additionally, the system will enable realistic fault simulations mimicking actual CCBII braking system malfunctions. Trainees can use the fault-setting assessment system installed on the right side of the driver’s cab—referencing both the "Static Test Protocol: Brake Control, Wheelset Anti-Slip Protection, and Auxiliary Devices" and the "CCBII Brake System Maintenance Manual"—to practice and configure specific training scenarios. Furthermore, all hard-wired mechanical and electrical faults incorporated into the system fully comply with the genuine fault-handling logic of the Knorr CCBII braking system.

Once the project equipment is fully constructed, it can be utilized for theoretical and hands-on teaching and practical training in areas such as learning the composition and operating principles of the CCBII braking system, mastering CCBII brake operation techniques, conducting locomotive traction and electro-pneumatic combined braking tests, gaining insights into locomotive air-source systems along with their maintenance and upkeep, understanding and maintaining locomotive bogies, performing basic brake system maintenance and repairs, handling maintenance and debugging of CCBII brake cabinet components, and addressing typical CCBII brake system failures. This setup will enable railway locomotive students to become proficient in operating electric locomotive braking systems, grasp emergency response procedures for fault scenarios, and acquire the skills needed for inspecting, maintaining, and servicing related equipment. Moreover, the integrated "teaching, learning, and doing" comprehensive training facility for electric locomotive braking systems—made possible by the advanced teaching management platform and faculty terminals installed in the dedicated theory classroom—creates the ideal environment for trainees to practice operating the system under a variety of realistic conditions. Students will engage in immersive, real-world-like learning experiences within the lab, simulating actual electric locomotive braking system operations. This includes hands-on activities such as studying the structure and principles of the CCBII braking system, troubleshooting common CCBII system faults, and undergoing rigorous assessment exercises—all designed to ensure that trainees develop the expertise required to excel in both routine operations and emergency situations. Finally, upon completion of the equipment installation, the facility will also serve dual purposes: supporting certification training and examinations for locomotive drivers, as well as hosting competitive events like locomotive driver skill competitions.

II. Overview of Features

This training system can carry out the following practical training activities:

Driver Console Training Project

1. Control Console Structure and Layout Training;

2. Display Unit Inspection Training;

3. Driver's console panel and cabinet inspection training;

4. Practical training on the operation of individual functional components;

5. Control Console Wiring Inspection Training;

Pending practical training content

Wind Source Piping System Training Project

1. Practical Training on Understanding and Maintaining the Air Supply System Piping for Locomotive Brake Systems

2. Air Compressor Awareness Training Project;

3. Air Compressor Inspection Training Project;

4. Practical Training on Understanding the Structural Principles of Safety Valves;

5. Recognition of the emergency vent valve structure and hands-on practice for venting exercises;

6. Training on recognizing the cab valve structure and practicing emergency brake activation procedures.

Pending practical training content

CAB-B Brake Cabinet / CCBII Brake Cabinet Training Project

1. CAB-B/CCBII Brake System Operation and Maintenance Training Exercise;

2. CAB-B/CCBII Brake System Disassembly and Assembly Training Exercise;

3. CAB-B/CCBII Brake System Valve Component Inspection and Maintenance Training Exercise;

4. CAB-B/CCBII Brake System Wiring and Cabling Training Exercise;

Pending practical training content

Locomotive Brake Tooling Training Project

1. Practical training on the inspection, maintenance, and upkeep of locomotive bogie brake units;

2. Locomotive Brake Unit Brake Pad Disassembly and Assembly Training;

3. Practical training on reading and leak detection for the bogie air piping system;

4. Bogie Wheel Diameter Measurement Training;

Interactive Software Training Project

- Brake System Main Equipment Recognition Training;

- Circuit Principles Hands-On Training;

3. Practical Training on the Pneumatic Circuit Logic of the Brake Cabinet;

4. Five-Step Brake System Training and Assessment Practice;

5. Brake System Fault Simulation and Assessment Training;

6. Full-vehicle fault diagnosis and assessment training;

7. Conduct joint traction and braking training;

8. Simulated Driving Joint Training.